Engine Management Technology Engine Management Technology

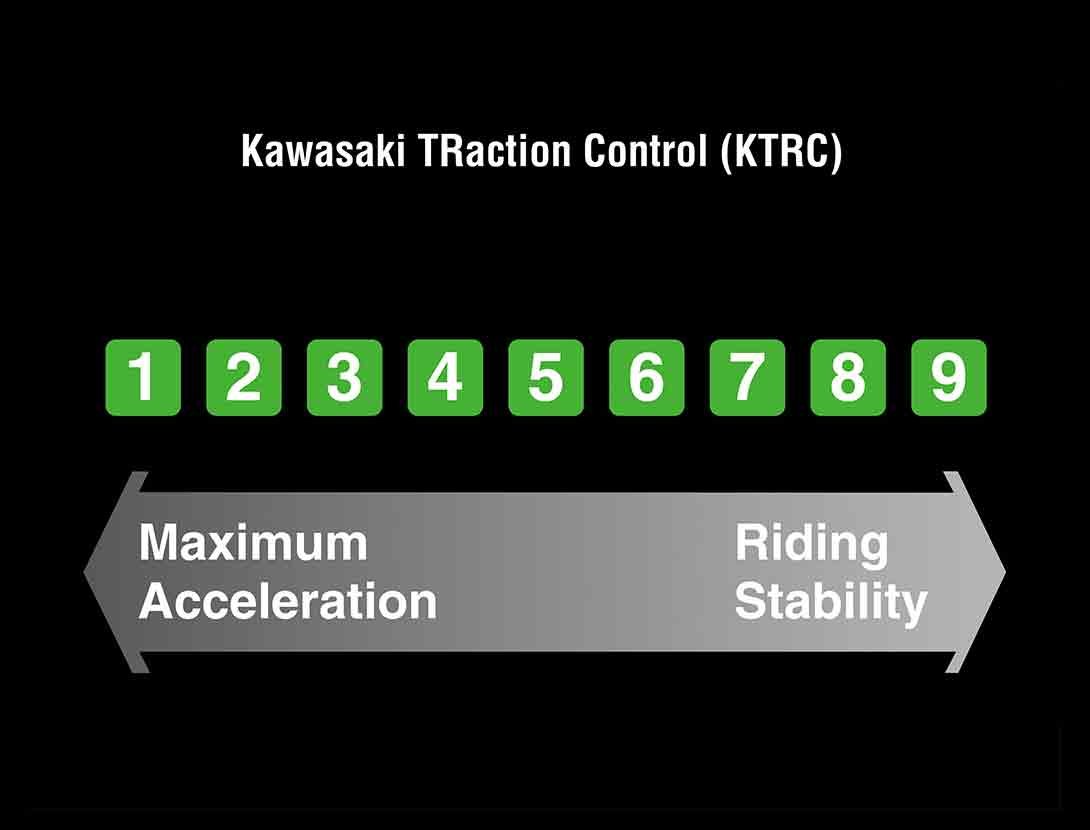

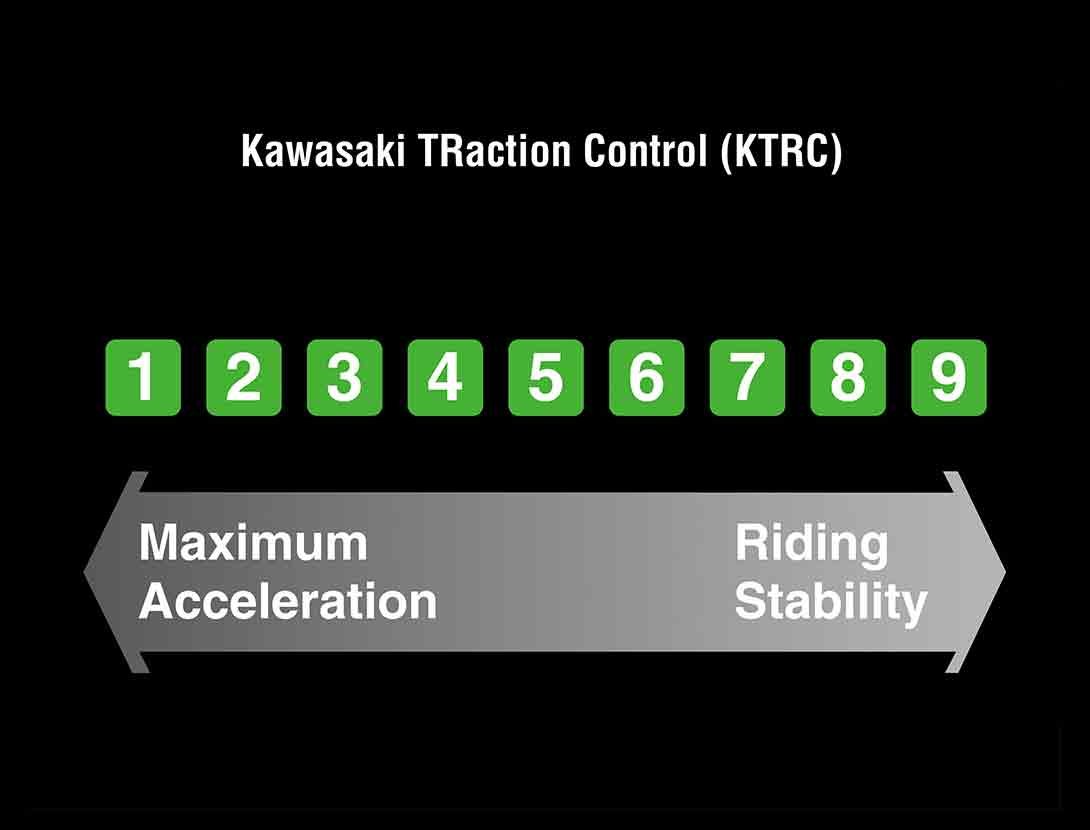

KTRC (KAWASAKI TRACTION CONTROL)

KTRC, Kawasaki's advanced traction control system provides both enhanced sport riding performance and the peace of mind to negotiate slippery surfaces with confidence. Multiple rider-selectable modes (the number of modes varies by model) offer progressively greater levels of intrusion to suit the riding situation and rider preference.

Less intrusive modes maintain optimum traction during cornering. Designed with sport riding in mind, they facilitate acceleration out of corners by maximizing forward drive from the rear wheel. And because Kawasaki’s sophisticated software bases its dynamic analysis on the chassis’ orientation relative to the track surface (rather than relative to a horizontal plane), it is able to take into account corner camber, gradient, etc., and adapt accordingly.

In the more intrusive modes (and for some models, in any mode), when excessive wheel spin is detected, engine output is reduced to allow grip to be regained, effectively enabling riders to negotiate both short, slippery patches (train tracks or manhole covers) and extended stretches of bad roads (wet pavement, cobblestone, gravel) with confidence.

Models equipped with IMU incorporate chassis-orientation feedback to offer even more precise management. |

ECONOMICAL RIDING INDICATOR ECONOMICAL RIDING INDICATOR

Using high-precision electronic control for engine management, Kawasaki models can achieve a high level of fuel efficiency. However, fuel consumption is greatly affected by throttle use, gear selection, and other elements under the rider's control. The Economical Riding Indicator is a function that indicates when current riding conditions are consuming a low amount of fuel. The system continuously monitors fuel consumption, regardless of vehicle speed, engine speed, throttle position and other riding conditions. When fuel consumption is low for a given speed (i.e. fuel efficiency is high), an "ECO" mark appears on the instrument panel's LCD screen. By riding so that the "ECO" mark remains on, fuel consumption can be reduced.

While effective vehicle speed and engine speed may vary by model, paying attention to conditions that cause the "ECO" mark to appear can help riders improve their fuel efficiency – a handy way to increase cruising range. Further, keeping fuel consumption low also helps minimize negative impact on the environment. |

Dual Throttle Valves

Late-model sport bikes often use large-bore throttle bodies to generate high levels of power. However, with large diameter throttles, when a rider suddenly opens the throttle, the unrestricted torque response can be strong. Dual throttle valve technology was designed to tame engine response while contributing to performance.

On models with dual throttle valves, there are two throttle valves per cylinder: in addition to the main valves, which are physically linked to the throttle grip and controlled by the rider, a second set of valves, opened and closed by the ECU, precisely regulates intake airflow to ensure a natural, linear response. With the air passing through the throttle bodies becoming smoother, combustion efficiency is improved and power is increased. |

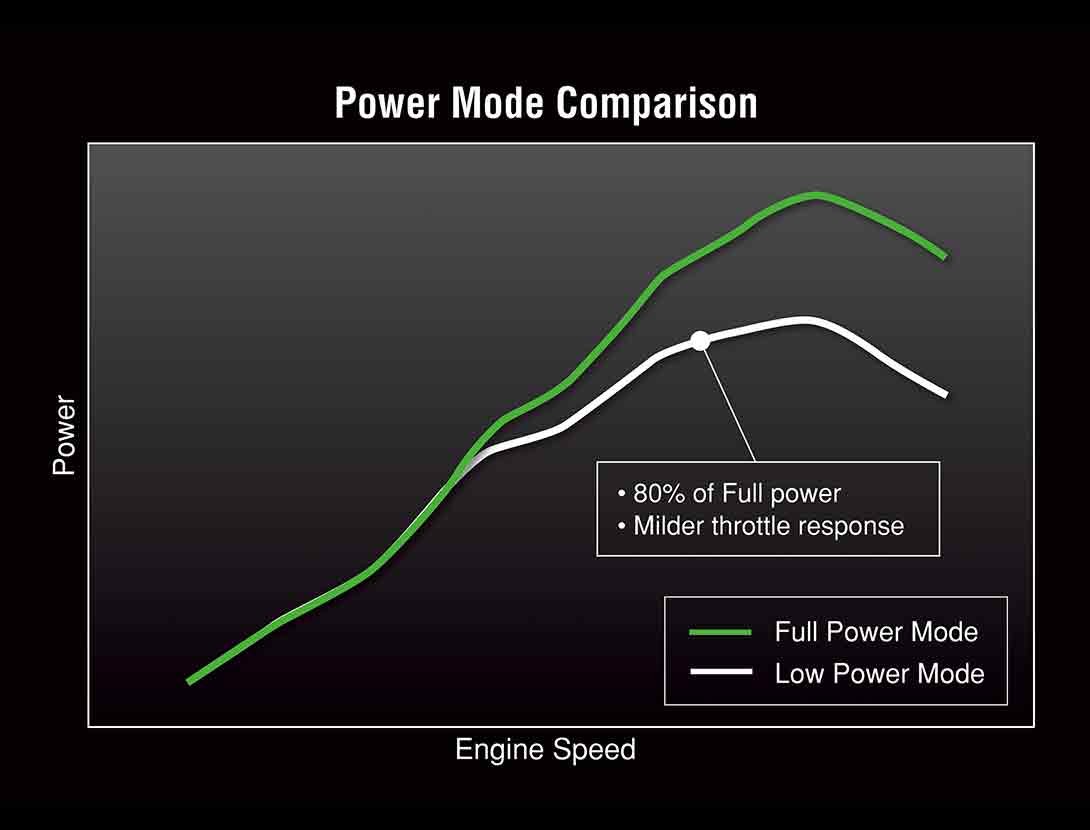

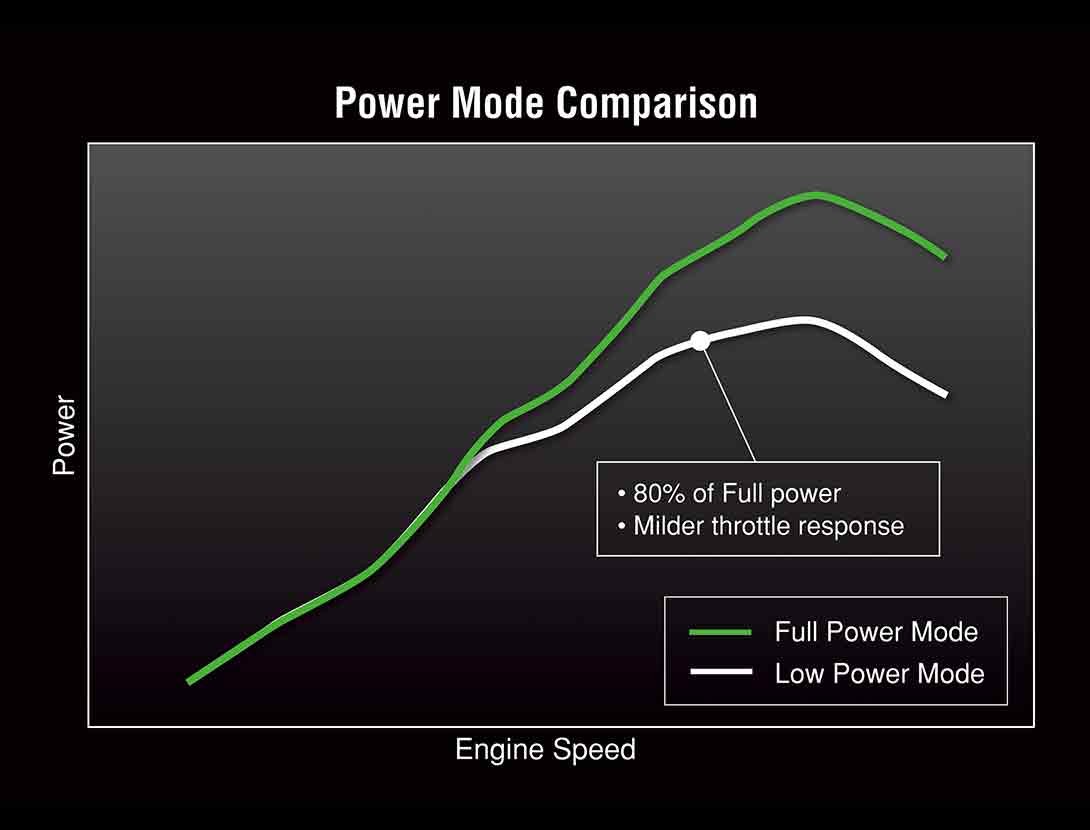

POWER MODES

Models equipped with multiple Power Modes offer riders an easily selectable choice of engine power delivery to suit riding conditions or preference. In addition to Full Power mode, one (Low) or two (Middle, Low) alternate mode(s) in which maximum power is limited and throttle response is milder are provided. |

Chassis Management Technology

ABS (ANTI-LOCK BRAKE SYSTEM)

Kawasaki ABS systems use front and rear wheel sensors to constantly monitor wheel speed. Should information from either of the sensors indicate that wheel lock has occurred, the ABS ECU directs the pump in the ABS unit to modulate brake fluid pressure (releasing and reapplying pressure so that traction can be regained) until normal operation resumes. ABS offers rider reassurance that contributes to greater riding enjoyment. |

MONOCOQUE FRAME

Kawasaki's monocoque frame is a hollow composite of aluminum parts. Originally conceived by Kawasaki engineers, it uses the engine as a fixed member so that chassis rigidity is formed not only by the frame, but the combination of the frame and engine together. Joining the engine and front and rear suspension units, the hollow box-style frame envelops the engine from above. In addition to being made from lightweight materials, its main section also acts as the air cleaner box and battery box, enabling parts to be reduced for even greater weight savings. Further, because the frame does not run beneath or alongside the engine, the chassis can be made very compact. Especially on large-displacement models, the slim chassis design of the aluminum monocoque frame contributes to ease of riding.

The aluminum monocoque frame was originally developed by Kawasaki in the 1980s for their World Grand Prix works racer. In an era where steel pipe frames were the norm, the aluminum monocoque frame that debuted on the KR500 took the world by surprise. First featured on a mass-production model on the 2000 Ninja® ZX™-12R, this original Kawasaki technology has evolved and can be found on some of our large-displacement flagship models. |

Engine Management Technology

Engine Management Technology ECONOMICAL RIDING INDICATOR

ECONOMICAL RIDING INDICATOR

FEATURING:

ADDITIONAL VEHICLE FEATURES: